Introduction: The Importance of Surface Finishes in Stainless Steel Sheets

Surface finish is a critical factor in the performance and aesthetics of stainless steel sheets. From industrial applications to architectural designs, the surface finish determines not only the appearance but also the durability and functionality of the material. Stainless steel sheets suppliers offer a wide range of finishes tailored to specific needs, making it essential to understand the options available. This article explores the various surface finishes, their benefits, and applications.

1. Mill Finishes: The Default Option for Stainless Steel Sheets

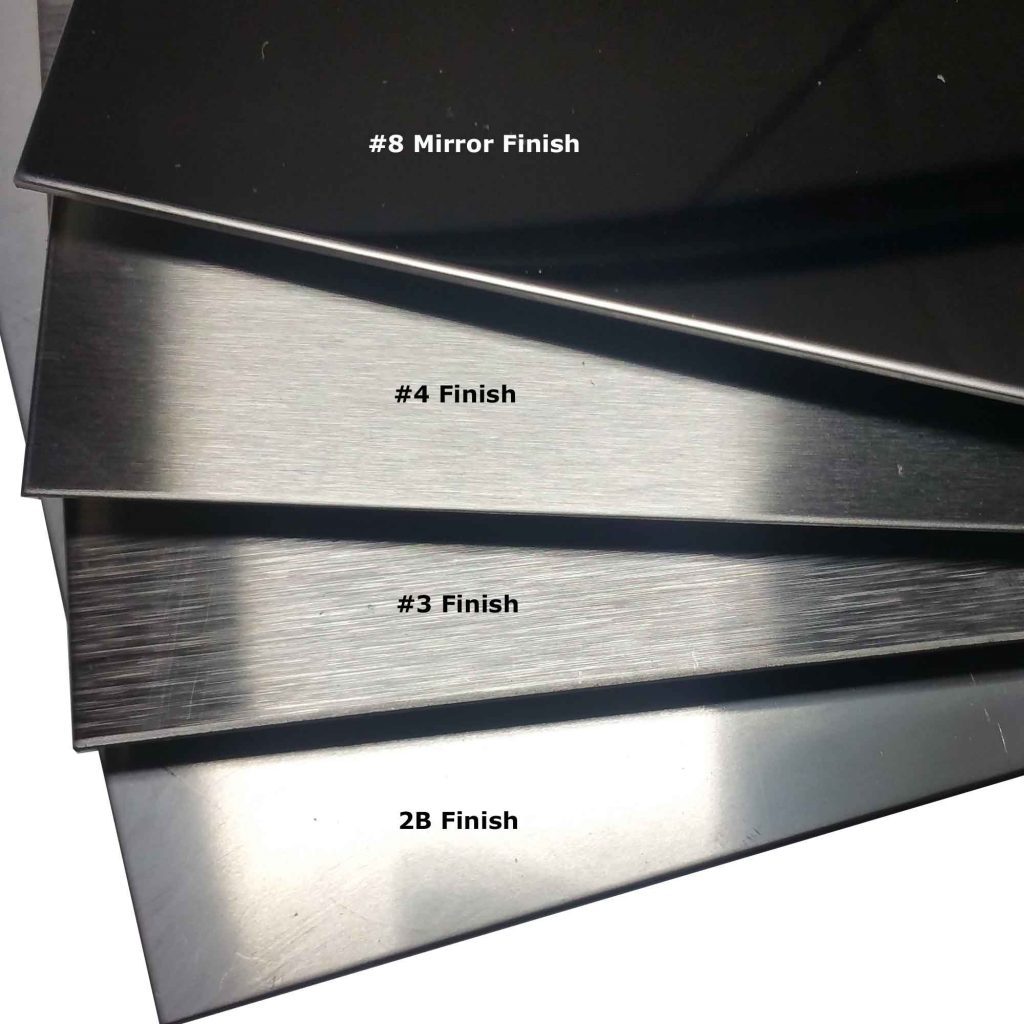

Stainless steel sheets with mill finishes are produced directly after rolling, offering a raw, unpolished appearance. These finishes, labeled as 1D, 2B, or No. 4, are ideal for applications where functionality takes precedence over aesthetics.

- 1D Finish: This is a coarse, non-reflective finish achieved through hot rolling and annealing. It’s commonly used in industrial applications like furnace parts and chemical tanks.

- 2B Finish: The 2B finish is smoother and semi-reflective, achieved through cold rolling followed by annealing and pickling. It is highly versatile and used in kitchen equipment and automotive parts.

- No. 4 Finish: Known as a brushed finish, No. 4 is produced by polishing the sheet with abrasive belts, giving it a consistent grain texture. Stainless steel sheets suppliers often recommend this finish for architectural and decorative applications.

2. Polished Finishes for Enhanced Aesthetics

Polished stainless steel sheets are widely used in settings where aesthetics are paramount. The polishing process improves the sheet’s appearance, making it ideal for decorative and high-visibility applications.

- Mirror Finish (No. 8): Achieved through extensive polishing, the mirror finish offers a high-gloss, reflective surface. It’s often used in elevators, signage, and luxury interiors.

- Satin Finish: This finish combines elegance with subtlety, providing a smooth surface without the high reflectivity of a mirror finish. Applications include furniture, appliances, and retail displays.

Polished finishes also improve the corrosion resistance of stainless steel sheets, as the smoother surface minimizes the accumulation of contaminants.

3. Patterned and Textured Finishes for Unique Applications

Patterned and textured stainless steel sheets are produced using advanced mechanical and chemical processes, offering unique designs and functional benefits. These finishes are increasingly popular for architectural and industrial uses.

- Embossed Finishes: Patterns are pressed onto the sheet, creating a raised texture. This finish enhances grip and is commonly used in flooring, escalator panels, and industrial walkways.

- Etched Finishes: Through chemical etching, intricate designs are applied to the surface of the sheet, making it suitable for decorative panels and artistic installations.

Stainless steel sheets suppliers often customize patterned finishes to meet the specific design requirements of their clients, adding versatility to the material.

4. Bead Blasted and Matte Finishes for Subdued Aesthetics

Bead blasting involves propelling small glass or steel beads onto the surface of stainless steel sheets, resulting in a uniform matte finish. This process is ideal for applications requiring subdued aesthetics and non-reflective surfaces.

- Benefits of Bead Blasted Finishes: They are non-glare and fingerprint-resistant, making them suitable for public spaces and transportation interiors.

- Applications in Industrial Settings: Matte finishes are also used in equipment where light reflection could interfere with functionality.

Many stainless steel sheets suppliers offer matte finishes to clients seeking a balance between form and function.

5. Colored Finishes for Innovative Design Possibilities

Technological advancements have enabled the creation of colored stainless steel sheets, expanding their aesthetic potential. The coloring process involves physical vapor deposition (PVD) or electrochemical techniques, ensuring durability and consistency.

- Popular Colors: Black, gold, bronze, and blue finishes are among the most sought-after options.

- Applications: Colored finishes are widely used in luxury interiors, modern architecture, and decorative signage.

Colored finishes from reliable stainless steel sheets suppliers maintain their appearance over time, resisting fading and discoloration.

6. Custom Surface Treatments for Specialized Requirements

In addition to standard finishes, stainless steel sheets suppliers offer custom treatments to meet industry-specific needs. These treatments enhance the material’s performance in challenging environments.

- Anti-Fingerprint Coatings: A transparent layer applied to the surface prevents smudges, making it ideal for electronic appliances and touchscreens.

- Anti-Bacterial Coatings: These coatings are used in medical and food processing applications to ensure hygiene and reduce contamination risks.

- High-Reflectivity Coatings: For solar panels and energy-efficient systems, high-reflectivity finishes enhance performance by reflecting light and heat.

Custom finishes enable stainless steel sheets to excel in niche applications, showcasing their versatility.

7. Choosing the Right Finish with the Help of Stainless Steel Sheets Suppliers

Selecting the appropriate surface finish depends on the intended application, environmental conditions, and aesthetic requirements. Reputable stainless steel sheets suppliers provide valuable guidance, ensuring their clients receive the best materials for their projects.

- Industrial Applications: Coarser finishes like 1D or bead blasted are often preferred for durability and functionality.

- Decorative Applications: Polished and patterned finishes elevate the visual appeal of architectural designs.

- Hygienic Environments: Smooth and anti-bacterial finishes are essential in food processing and healthcare settings.

Working with experienced suppliers ensures the material meets both technical and aesthetic specifications.

Conclusion: Unlocking the Potential of Surface Finishes

The surface finish of stainless steel sheets significantly impacts their performance, durability, and appearance. From polished and matte finishes to patterned and colored options, the variety available allows these sheets to excel in diverse applications. By partnering with reliable stainless steel sheets suppliers, industries can access high-quality materials tailored to their needs.

Understanding these options empowers designers, architects, and engineers to make informed decisions, ensuring optimal results for every project. As the demand for versatile materials grows, stainless steel sheets with innovative finishes will continue to shape the future of modern design and manufacturing.